As pore pressure has a direct relationship with the subsurface movement behaviours in soil, it should be no surprise that piezometers are used frequently alongside ShapeArray to monitor deformation. Can ShapeArray be installed into the same borehole? Members of Measurand’s technical service team receive that question frequently.

The short answer is no. The installation of a piezometer into the same inclinometer casing is not recommended. The best practice recommended is for the instruments to be installed into separate boreholes. While both types of instrumentation require borehole installation, there is a number of reasons why these sensors can’t be installed into the same casing or borehole.

SAAV‘s patented off-the-reel cyclical installation enables direct installation into new and existing inclinometer casings. SAAV’s joints are held into compression with the sides of the casing by a spring box assembly and locked into place with a casing cap. Anything within that inclinometer casing—the cable for a piezometer for example—can potentially obstruct the fit which potentially could impact the tilt readings of the SAAV’s MEMS sensors, and the deformation data by extension.

Part of SAAV’s versatility is that it can also be installed vertically into PVC conduit to measure deformation. Robert Praeg, geotechnical instrumentation specialist, E.I.T., with Measurand’s technical services says that this method allows clients to install piezometers very close by to compare both sets of data within the area of interest.

There are several different types of piezometers (open and closed circuit) with different methods of reading data and sensor technologies. However, some of the most commonly used piezometers alongside ShapeArrays are vibrating wire piezometers. The best practice for the installation of vibrating wire piezometers is to fully grout them into a borehole with sensors placed at different elevations which allows pore-pressure measurements along the total length.

For situations where ShapeArray and Piezometers are located within the same area of interest to monitor pore pressure and deformation, Robert recommends an automated data acquisition system that can integrate readings from both sensors. He recommends the RSTAR system with a FlexDAQ by RST Instruments. In situations where several ShapeArrays are installed, Robert explains that with DTSAA, clients can wirelessly automate data collection to FlexDAQ as a central hub.

“The alternative being, multiple different hubs or you’re running cable underneath the soil,” Robert says. “But as you can imagine running and trenching a lot of cable and protecting with an added conduit can be quite time consuming, which almost defeats the value that ShapeArray provides—easy installation.”

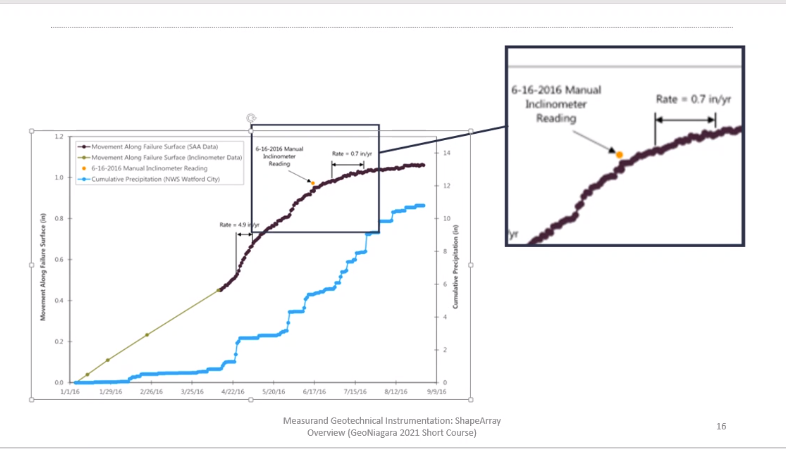

Ground movement, in many cases, is relative to pore pressure, Robert explains. An advantage of automated monitoring, he continues, is having the ability to compare two continuous streams of data to reveal more information about the project site. His example is a Department of Transportation project in the Midwest that collects accumulated precipitation data to evaluate alongside ShapeArray data to see if movement occurs during rain.

A helpful analogy to imagine the difference between seeing pictures of a sporting event in a newspaper versus watching a broadcast of the game in near real-time.

“You’re using your imagination almost to visualize what is happening in between and with this instrumentation, bridging the gap from the unknown to the known. Without that, if you’re getting the snapshots, it forces the designer to make a much more conservative approach to mitigate any risk of what could be the unknown: is there a slip failure surface in this area that we don’t know about?” Robert says. “Whereas, with more information, you’re able to ideally, put fewer resources into a conservative approach because you’re able to actually measure exactly what’s going on.”