Measurand’s Christiane Levesque and Mitchell Pollock recently presented a live webinar, Advances in deformation and settlement monitoring with ShapeArrayTM that covered the fundamentals of monitoring with ShapeArray, the recent design improvements to ShapeArray, along with the novel and atypical use-cases.

They also detailed how Measurand’s client-centric approach to product development has led to numerous ergonomic and installation improvements that increase both worker safety and installation speed.

This webinar covered:

We received several questions during the webinar that we’ve answered below:

Question: Is ShapeArray compatible with the FlexDAQ system?

Answer: Absolutely. There are many projects that are currently being monitored by ShapeArray instruments that are on the FlexDAQ loggers.

Q: Are there data logger platforms that integrates with SAASuite software, so we can get final results directly instead of post-processing?

A: At the moment, there are not too many. Most of them you would be looking at are part of our Orica Digital Solutions group of companies. The RSTAR Affinity digital suite, for example, which would allow you to do that automatically. And there’s also sensemetrics that has limited capabilities. Sensemetrics is capable of doing some of the main installations that we do, but it doesn’t cover everything that we have. We are currently working on something to make these integrations a little bit easier over time. And hopefully, we’ll see that being launched in short order.

Q: Are there any examples of using ShapeArrays for foundation installations?

A: We have customers that have used ShapeArray to monitor foundation projects. In terms of being able to share that data, that’s a little bit more complicated. I will tell you what the main applications people do with Foundation installations. Quite often it’s going to be about the excavations. People are going to be monitoring the excavations to verify that things are going as expected. We’ve had some people use it to monitor piles and do lateral loading of piles with great success. And we also have had people that have used it specifically to monitor settlement across a raft foundation during loadings. Those are the three main applications that we’ve seen. The most common application is excavation because that’s where the most movements are going to be.

Q: Does ShapeArray require a specific orientation for the installation? How do we verify the alignment of the instruments?

A: As far as vertical installations are concerned, yes, we do. But we don’t control the installation direction. To orient everything, we include a protractor that is sold with every order and that protractor is used to orient the ShapeArray.

There are two arrows on it that you use to orient the protractor in the direction of either the expected direction of movement or to known directions. Let’s say you wanted to map it to North. You could point the arrows North then measure to the X-mark on the on the instrument; it’s easy to do when you see it. During your data conversion, you just apply that angle and then it will do an angular rotation of all the ShapeArrays sensors so that the X direction is aligned with the expected direction (North in this example).

When we’re looking at horizontal or convergence installations, we don’t need to know what the orientation of the X and the Y components are. We get that information automatically.

Q: Does ShapeArray install in classic inclinometer casing?

A: Yes. Absolutely. You can install it inside an inclinometer casing. However, one of the reasons that we made ShapeArray the way that we did is so that you can install it in whatever you have as a casing, as long as the inner diameter (ID) matches our specs, you’re good to go. We have quite a few clients that install instruments into a perfectly smooth tube.

But one of the big advantages with ShapeArray is that people tend to install these instruments to retrofit existing installations, which usually means that you’re going to have an inclinometer casing. For example, you’ve been monitoring a borehole for some time and then you need to either automate it due to regulations or maybe it’s just too costly to keep sending somebody out, so you decide to it’s time to automate. Or the other case is that an inclinometer probe no longer fits the groove within the casing. Because ShapeArray doesn’t have wheels the instrument can navigate past through that area which allows you to continue monitoring the casing for much longer than what you would traditionally be able to do with just the inclinometer probe.

In short, you can use inclinometer casing if you want but ShapeArray can be installed into any casing or conduit with an inner diameter that matches our specs.

Q: How’s ShapeArray impacted by electromagnetic interference?

A: This is a more popular question than you would think. There’s two things to consider.

First off, we have the shield wire fully used in our instruments. This is something that’s not necessarily done with all instruments, but we use the shield wire to help reduce electromagnetic interference.

Second, in many cases, you can’t have the ShapeArray directly on or right adjacent to the source of electromagnetic interference. Ideally, you would usually have some distance but we have been as close a couple of feet. When in doubt, check in with our engineers. We will be happy to help.

Q: Is it possible to install ShapeArray on the spring line of the tunnel and monitor the horizontal and vertical settlement?

A: We can’t use ShapeArray to monitor horizontal deflection in this example, because of the way that the ShapeArray works.

One of the things is if you’re trying to measure along the length, right? You’re going to have essentially a horizontal installation. The reason it’s a 2D reading is because ShapeArrays work using MEMS accelerometers to measure tilt relative to gravity.

Let’s assume that we have something that’s horizontal and the tilt changes in one direction. Then what we’re able to do is basically see that one dimensional change. For what we measure, you can only see the settlement in terms of vertical, but you can’t see the horizontal deflection for the tunnel.

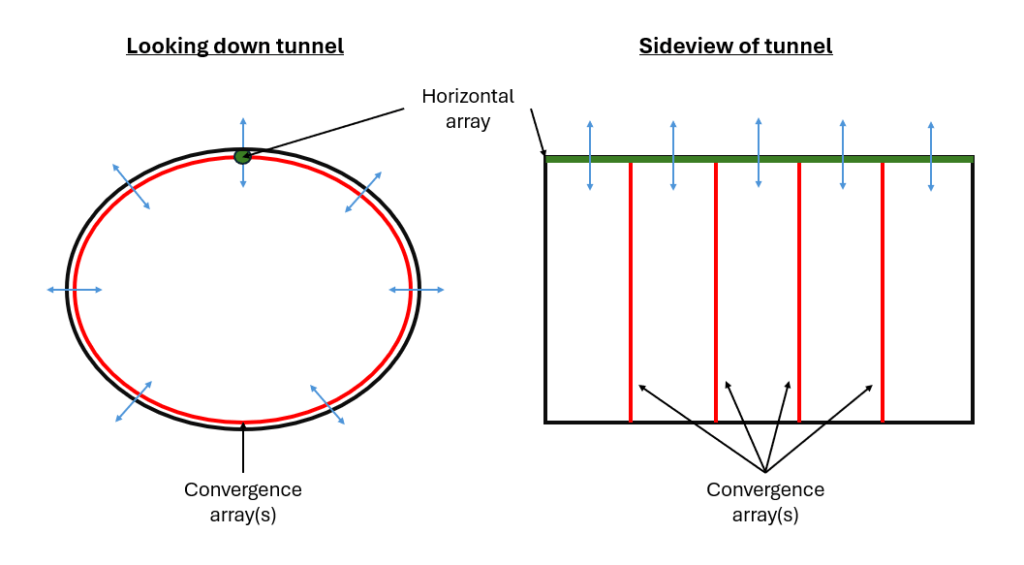

To achieve a better idea of movement in a tunnel, SAAX and be used alongside SAAV in Convergence. You would then be able to determine settlement along the length of the tunnel with the SAAX, and inward/outward movements (perpendicular to the SAAX) at certain intervals where the SAAVs in Convergence are placed. See attached drawing showing this approach, which I like to say resembles a ribcage for illustrative purposes.

This transcript has been edited for clarity. Watch the webinar on-demand to learn more about how ShapeArray can be used as a part of your monitoring strategy.