Wireless automated remote deformation monitoring is transforming how engineers collect data to ensure the safety and durability of their projects.

Through a network of interconnected technology, this real-time monitoring system delivers proactive risk management by evaluating structural and geographical deformations. It integrates geotechnical instrumentation such as sensors, data loggers, and gateways with communication networks to automate data processing.

Within such a system, the inclusion of ShapeArrayTM is pivotal for its success.

Automated monitoring and its innovative of digital geotechnical instrumentation represents a departure from traditional manual data collection.

Engineers in the past relied on measurements taken by hand to assess field performance. Today, advanced geotechnical instruments are often deployed in interconnected Industrial Internet of Things (IIoT) systems, automating data collection and transmitting this data wirelessly and remotely.

An automated data collection network is the sum of its parts. Meaning it’s crucial to choose geotechnical instruments that will integrate seamlessly, while also delivering the necessary reliability, scalability, and security.

Leveraging ShapeArray with RSTAR Affinity, an integrated system for geotechnical monitoring projects, can provide powerful and streamlined data automation.

Measurand’s flagship product, ShapeArray is a shape-sensing, inclinometer-style instrument that installs from a reel. Capable of collecting and displaying data in real-time, it’s used to monitor deformation of soil and structures, such as dams, tunnels, walls, and buildings.

When part of a wireless monitoring network, ShapeArray can deliver, wireless, remote, and automated data collection.

Developed by a team of experts in geotechnical sensor-manufacturing, RSTAR Affinity synergizes remote, wireless data collection with industry-leading instrumentation. It delivers comprehensive support to geotechnical monitoring projects, harnessing the combined power of:

RSTAR Affinity offers an end-to-end solution delivering all functions in the data chain from a single source. Integrating this system with ShapeArray creates an incomparable integrated network for wireless automated remote deformation monitoring.

Building and maintaining a successful data collection deployment strategy depends on several factors. Some key pre-requisites include:

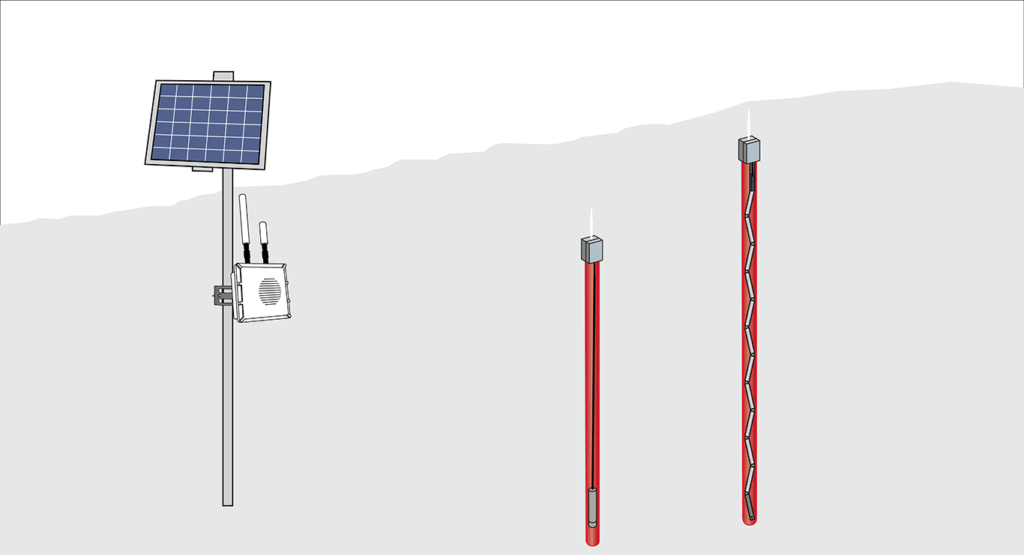

Your automated system will be simple or complex as its project necessitates. However, a basic data collection deployment for slope monitoring could resemble:

Installed in an inclinometer casing on a slope, the ShapeArray connected to an RSTAR Affinity Data Logger collects deformation data. This data logger periodically collects data from the ShapeArray, transmitting it wirelessly to the RSTAR Affinity gateway that forwards data to a central server or cloud for storage and analysis.

Through this setup, geotechnical engineers can monitor data in real-time to detect early signs of landslides, allowing for timely risk mitigation.

Wondering how automated data collection could fit into your project’s geotechnical monitoring strategy? Watch our recent webinar, “Wireless Automated Remote Deformation Monitoring: How to Get the Most Out of ShapeArray,” hosted by Measurand’s Megan O’Donnell and Terra Insights’ Joseph Cormier.

In this recording, you’ll learn the different ways to approach data collection when using ShapeArray, from standalone manual data collection to the configuration of a fully automated and wireless network of connected data loggers. Discover how slick and easy it can be to deploy and configure a network for data collection.