Effectively measuring vertical and lateral displacement provides invaluable information to decision-makers on the performance of their structures. Whether it is a critical program such as supporting active construction or long-term condition monitoring of aging infrastructure assets, reliable data can help manage and mitigate risk. Clients need to compare ShapeArray vs digital in-place inclinometer systems to determine which monitoring solution is correct for them.

Manual probe inclinometers were introduced to the geotechnical field in the 1950s. Since the introduction of inclinometers, geotechnical instrumentation has evolved with advances in digital technology, which has led to the development of digital probes and in-place inclinometer systems (IPI). IPIs are still widely accepted today as the industry standard for long-term geotechnical monitoring. Whether a manual inclinometer or digital IPI, the principles behind the instrumentation remain the same.

ShapeArray is built upon these principles and has earned its description as a flexible, IPI-style geotechnical instrument since its release in 2006. The fundamental differences between a ShapeArray and an in-place inclinometer make it uniquely ideal for specific applications and monitoring requirements where a high degree of movement is expected to occur and/or higher rates of data sampling is needed.

When deciding which instrument will best meet your needs, and compliment your project requirements best, it is essential to understand these fundamental differences.

ShapeArrays offer a higher spatial resolution with a sensor position at 500 mm increments for vertical installations or 1000 mm for horizontal installations. This provides a dedicated sensor at every 0.5 m elevation with a per segment resolution of 0.5 mm.

| Vertical Application | Points of data |

| IPI (2 M gauge length) | 25 |

| SAAV (0.5 m segment length) | 100 |

| SAAV (0.25 m segment length) | 200 |

| Horizontal Application | Points of data |

| IPI (2 M Gauge length) | 25 |

| SAAX (1 m segment length) | 50 |

| SAAV (0.5 m segment length) | 100 |

| SAAV (0.25 m segment length) | 200 |

Depending on the application, ShapeArray can provide up to eight times the spatial resolution of an IPI. Regarding price, Measurand has found that an IPI with a 2 m gauge length (spacing) is a similar cost to a ShapeArray with 500 mm segments, not including the labour hours associated with implementing the systems (refer to ease of install for more details around labour hours).

The accuracy specification of a ShapeArray is +/- 1.5 mm relative to the baseline reading for a 32 m (64 x 500 mm segment) length. This is an installed, field-tested value that users can expect with each model ShapeArray, not a specification that was derived from testing in a controlled lab environment.

An in-place inclinometer deformation accuracy such as RST’s in-place inclinometer system measures the same accuracy as a ShapeArray when comparing arc seconds, however ShapeArray yields a higher level of deformation accuracy than a traditional IPI system.

| ShapeArray (0.5 m SAAV segment length) | IPI (2 m Gauge length) | |

| Arc Seconds | +/- 1 | +/- 1 |

| Deformation Accuracy | +/- 1.5 mm over 32 M | +/- 2 mm over 30 M |

Specification sheet: SAAV

The unique construction of ShapeArray has shown exceptional resilience to deformation on several projects. Most notably, a roadway failure in Minnesota, USA, vertically installed ShapeArrays withstood a dramatic slope failure with a deformation magnitude totalling 3 m. Depending on the degree of anticipated movement and the potential for shear, ShapeArray can potentially continue monitoring, during and after a shear has occurred. Whereas the rigidity of an IPI system means it is more prone to damage in higher movement areas.

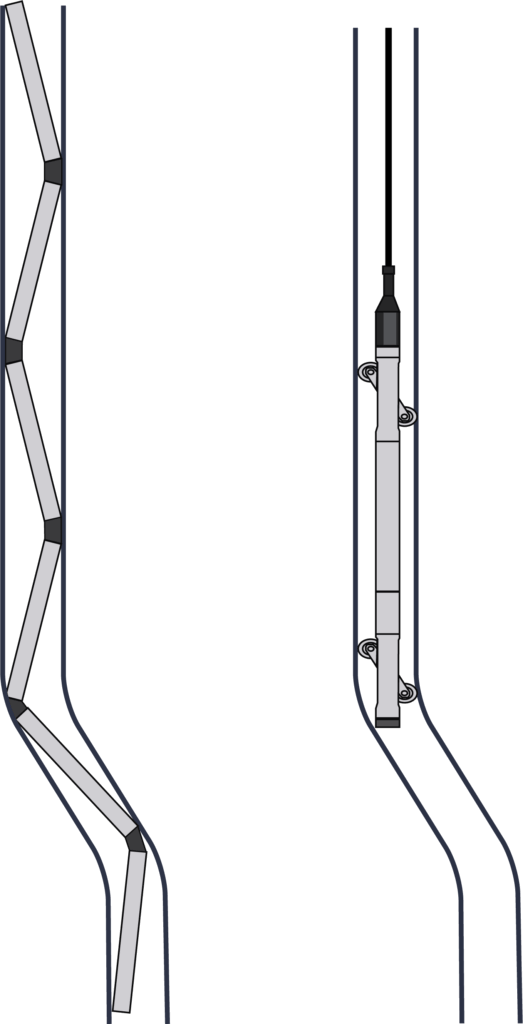

The flexibility offered by the ShapeArray and its ability to retrofit multiple sizes of standard inclinometer casing means it can more easily ‘snake’ into a damaged or deformed casing. Whereas an IPI will not be able to install into damaged, deformed or spiralized casing.

For vertical installations, ShapeArray does not use the casing grooves or centralizers, so spiral corrections are unnecessary, and the client has the option of substituting standard inclinometer casing with a lower cost PVC conduit (or similar material). Measurand’s patented cyclical installation method means SAAV can be installed in 27 mm and 47-100 mm casing, making it the most adaptable instrument on the market.

In-place inclinometers require specialized inclinometer casing to be installed, as well as spiral corrections to adapt to the alignment of the grooves.

Support article: Installing SAAV into existing inclinometer casing

Implementing ShapeArray into your monitoring strategy is quick and relatively low-cost. Each instrument arrives pre-calibrated and ready for installation off the reel. As you can see in the video below, a 50 m ShapeArray is easily deployed from the reel by two technicians without specialized training. The time required to install varying lengths of ShapeArray is not significantly different. In many cases, assuming typical site accessibility, users can install ShapeArray and start collecting data in 75 percent less time than traditional IPI systems on the market.

The ease at which the ShapeArray is installed equals fewer labour hours, which makes the instrument ideal for projects that need a quick turnaround time or pose hazardous conditions for field technicians.

IPI’s require on-site assembly and the use of special equipment depending on the length. Also, the overall length also plays a significant role in the amount of time required to install an in-place inclinometer. For a 50 m IPI system, a typical installation can take more than two hours.