Measurand launched SAAX in 2014 because our clients needed a rugged, cost-effective solution for real-time ground settlement, subsidence, rail-line deformation, and pipeline monitoring. Now, in 2020, Measurand is proud to announce the next step in the evolution of the most rugged and durable ShapeArray we sell—SAAX model 003.

SAAX is purpose-built for heavy-duty horizontal installations for ground settlement and displacement monitoring at a project budget-friendly price-point.

Long-time Measurand distributor, Cautus Geo, submerged a number of overlapping SAAX ShapeArrays to create a single, nearly kilometre-long, deformation profile along the floor of Gilhusbukta Bay, Norway.

SAAX ShapeArrays were installed below the busy streets of Los Angeles to monitor the construction of 1.8 km of twin-tube bored tunnels as part of LA Metro’s light rail extension. Extremely precise monitoring was needed to ensure that ground movement did not exceed the maximum allowable displacement of 13 mm and that adjacent buildings and utilities were not damaged during the tunnel boring machine’s (TBM) drive.

SAAX is currently installed to measure the effects of frost-heave near a commercial railway as part of a multi-year research project funded by the National Research Council (NRC).

Changes in ground movement can be caused by a variety of natural and human forces and the timeline of these changes varies greatly from project to project. The ground settlement process can range from days to decades depending on factors such as soil permeability and drainage patterns.

Ongoing monitoring of any project is central to preventing damage to the construction caused by unexpected ground movement. Continued monitoring, post-construction, allows for the detection of settlement anomalies as early as possible. This allows for early intervention and adjustments to the construction before more serious damage has a chance to occur.

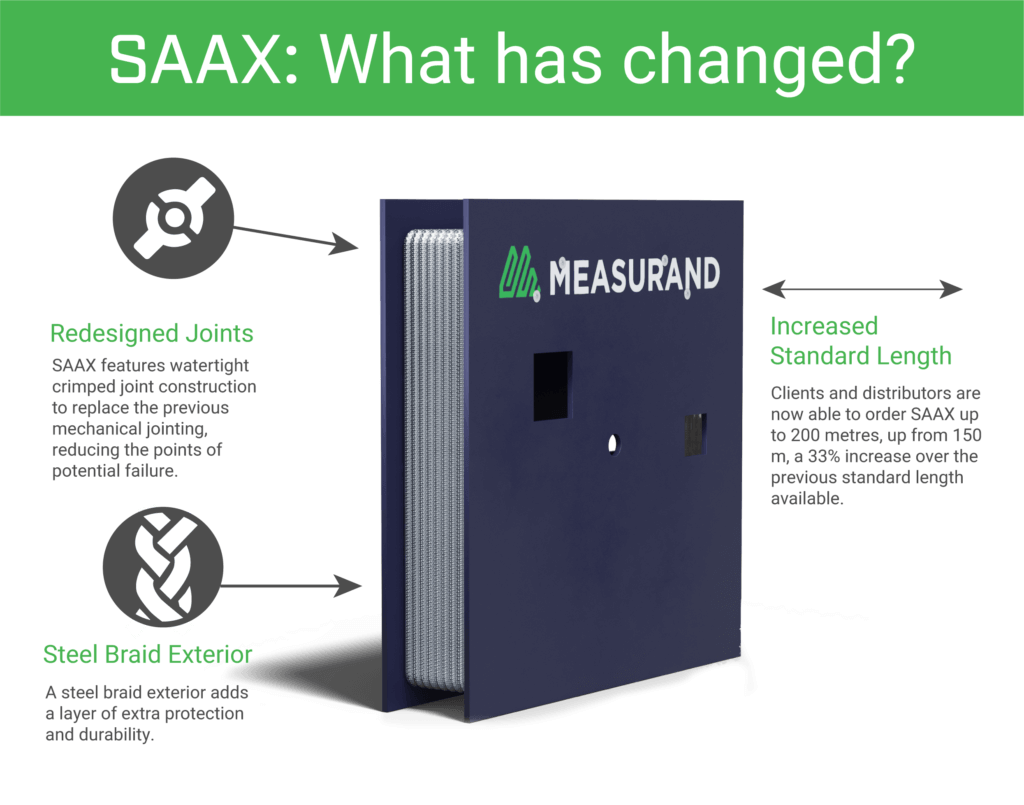

SAAX features watertight crimped joint construction to replace the previous mechanical jointing, reducing the points of potential failure.

A new steel braid exterior adds a layer of extra protection and durability to SAAX, similar to the steel braid that has been part of the SAAV since 2017, and the legacy ShapeArray model SAAF.

Clients are now able to order a standard length SAAX up to 200 metres, up from 150 metres, a 33% increase over the previous standard length available. For SAAX orders over 200 metres, contact Measurand sales.

SAAX still boasts heavy-duty waterproof construction—1000 mm segments of heavy-walled stainless-steel tubing with robust, flexible joints, now wrapped in a layer of steel braid.

SAAX installs with the same horizontal installation kit as the previous SAAX model.

SAAX remains the most cost-effective ShapeArray to create long-length deformation profiles for soil settlement monitoring.

Every ShapeArray we sell contains the same triaxial MEMS accelerometers that produce the deformation data that our clients trust and rely on.