Built for rapid deployment and repeated use. The instrument of choice for one-shot verification of the alignment of jet-grouting holes. Thick-walled 500 mm segments provide great spatial detail and resist damage.

Designed to be used, moved, and re-used as quickly as possible, SAAScan is ideal for applications where borehole shape must be measured repeatedly—jet grouting and borehole drilling, for example. SAAScan’s robust and durable construction combines twist-resistant joints and thick-walled stainless steel segments. The construction contains a compact array of MEMS gravity sensors.

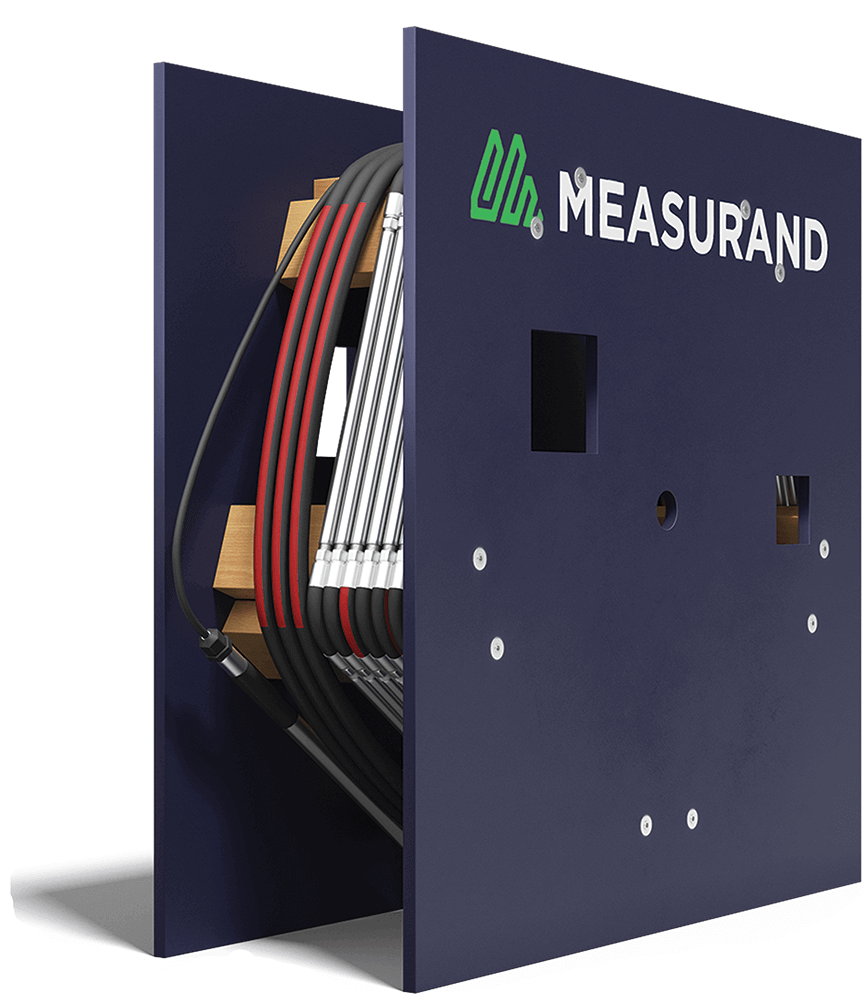

SAAScan saves time and money. It is a reel-based system enabling the measurement of hundreds of holes. A unique extension hose and cable terminator allows SAAScan to remain anchored on the reel while the rest of the array length is installed to collect accurate real-time data.

SAAScan’s segment length is 500 mm. SAAScan can be manufactured to a standard length of up to 50 m. Contact Measurand to inquire about custom lengths. All ShapeArrays™ are manufactured in an ISO 9001 certified facility.