As a state-of-the-art geotechnical deformation monitoring instrument, ShapeArrayTM has unique power and communications requirements. These come into play during installation and standalone manual data collection. Measurand offers two portable ShapeArray interfaces to help clients set up and use their ShapeArrays—the Field Power Unit (FPU) and the Portable Diagnostic Unit (PDU). In this post, we explore the comparisons between the two along with the most appropriate use-cases for each device.

The Field Power Unit and Portable Diagnostic Unit are easily transported devices designed to provide power to Measurand ShapeArrays. These devices also facilitate communication between a PC running Measurand’s SAARecorder software, or an Android device running the SAADroid app, and a connected ShapeArray. While both the devices provide clients with the same functionality and utility, there are some differences in terms of form factor and battery capacity.

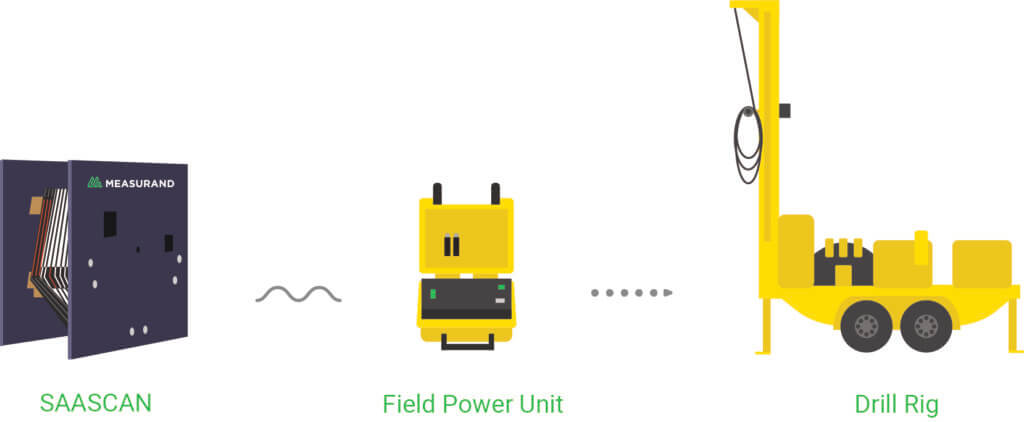

Field Power Unit

The ShapeArray Field Power Unit (FPU) is a portable, rugged, all-in-one power and communication device designed specifically for manual data collection in the field. Everything needed for the field is enclosed within a lightweight, water-resistant case. The FPU contains a rechargeable 12V 6 Ah battery, 5-pin and 4-pin communication ports, and Bluetooth for close-quarters wireless data transmission. An auxiliary 4-pin terminal block can be used to power other equipment such as a radio modem or voltmeter.

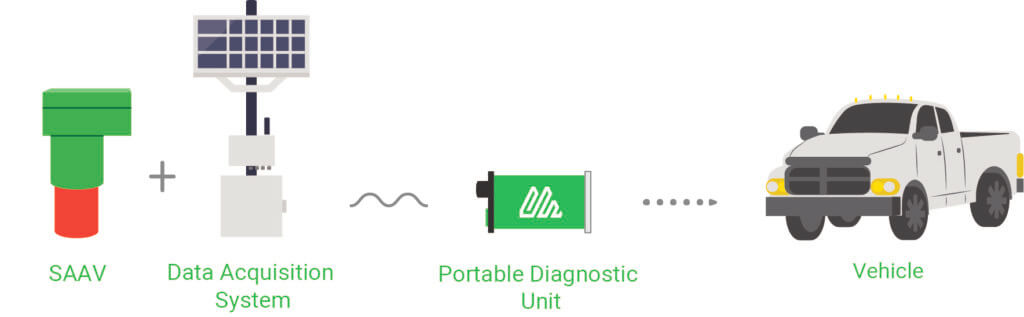

Portable Diagnostic Unit

The Portable Diagnostic Unit, introduced in 2021, is a compact power and communication device designed to quickly test and verify ShapeArray installations prior to configuration for automated data collection. Measurand designed the Portable Diagnostic Unit (PDU) so clients have a portable, cost-effective way to verify SAAV’s patented cyclical installation, ensuring your ShapeArray delivers the highest quality deformation data possible.

Measurand’s PDU contains a 10.80 V, 3350 mAhr Lithium-Ion battery pack that can be fully charged in under two hours. The PDU is field-ready with the following accessories included inside a lightweight, water-resistant carrying case: a USB-C Power Delivery Charger, USB-C Power Delivery Car Charger, a USB-C cord, and a USB-C to USB 2.0 Type-A Adapter.

The FPU and the PDU share the same core functionality for powering and communicating with ShapeArrays. Clients can trust the FPU and PDU for three important applications—installation verification, manual data collection, and diagnostics.

Installation verification

SAAV’s patented cyclical installation system enables a stable fit into new or existing casings. Measurand recommends that clients verify the installation of their SAAV with our software suite and either a PDU or FPU. This ensures the ShapeArray is compressed within the casing and is ready to collect the best quality data possible.

Manual data collection

While clients tend to choose ShapeArray for automated data collection, there are situations where manual data collection is preferred. Clients can connect to a ShapeArray with an FPU or PDU along with a PC or Android device and perform manual data collection.

Diagnostics

There may be situations when clients need to collect diagnostic information from a ShapeArray. With Measurand’s SAARecorder software, included in our SAA Suite software, users can run a series of diagnostic tests on a connected ShapeArray to generate a text report containing the results. This is helpful for diagnosing the health of the ShapeArray and for troubleshooting any issues with the instrument.

Measurand’s technical services team lead, Matthew Miller, explains that a client’s application will help determine which device is going to be preferred. For clients using SAASCAN, the FPU’s s superior battery capacity makes it the ideal device to accommodate the instrument’s power consumption.

“Based on the implementation of SCAN—the deployment of SCAN in the field, you are running maybe eight to 12 hours a shift. You are chasing drill rigs around with this instrument. You don’t want to have to recharge or swap out units multiple times,” Matt explains.

Whereas the PDU was designed to be as compact as possible for geotechnical installations associated with SAAV, SAAV Extend, and SAAX, Matt continues. He notes that the PDU can fast-charge with a car charger, which is ideal for clients doing shorter periods of work—installing multiple ShapeArrays, for example—rather than a whole day’s work of readings like an FPU. Also, because of a smaller battery and compact design, PDU is also more affordable than the FPU.

“For SAAV vertical installs, the PDU is a very highly recommended tool for that purpose,” Matt adds. “For the support side of things if you run into issues, then it is a great thing to have in the toolbox to be able to pull up and run diagnostics and give us information that we can review to help the client in the field.”

Ultimately, the FPU and the PDU possess the same functionality, albeit with different form factors, battery capacity, and price points. Where a client intends to use them also plays a role.

“Perhaps you don’t have access to a vehicle, or you might be taking a helicopter in for the day and you don’t have a guaranteed power supply to charge it,” Matt says. “An FPU might give you that peace of mind, knowing that it is rated for a full-continuous days’ work where PDU gives you a smaller window on a more specific-use case basis.”